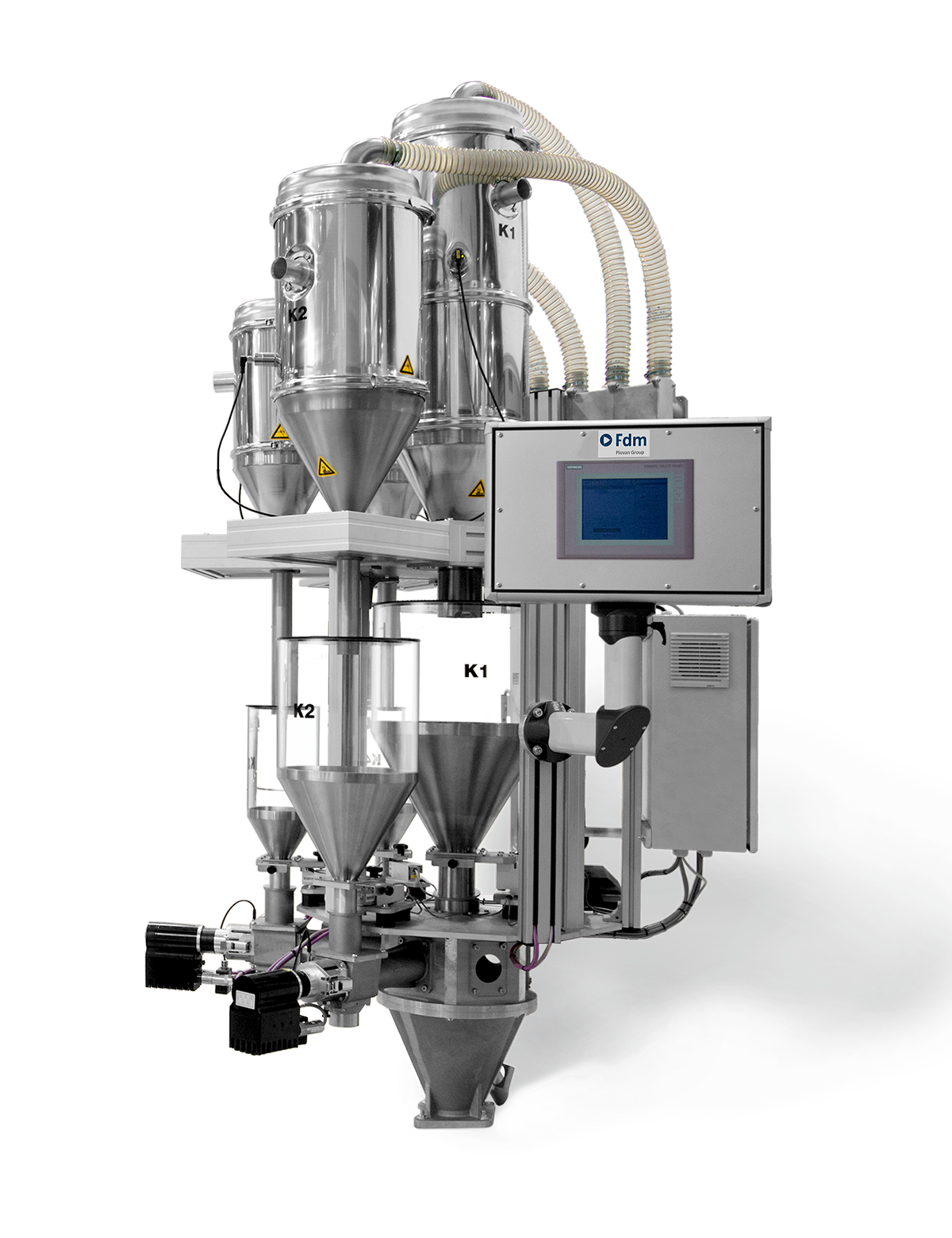

Die GDS-Serie ist die richtige Lösung, wenn eine kontinuierliche Dosierung mit höchster Genauigkeit erforderlich ist.

Das Gerät befindet sich oberhalb des Extrudereinlaufs und wird über Vakuumabscheider beschickt.

Hochwertige Wägezellen messen den Gewichtsverlust der einzelnen Komponenten und die Servoantriebe regeln den Durchsatz der einzelnen Komponenten.